Evaluating excess moisture and water damage in building materials can be challenging, especially if no visible water stains, mold growth, or wet/musty odors are present. Mold growth can occur when water has moistened porous materials for longer than 48 hours.

The following is guidance on using moisture measuring devices (MMDs) to determine moisture concentrations in building materials.

Water may originate or result from:

- Leaks in the building envelope (e.g., roof leaks, poorly sealed windows, wet basements)

- Releases from plumbing, sprinkler, or HVAC (heating, ventilation and air-conditioning) systems

- Humid air condensing on surfaces

- Excess humidity (over 70%) over an extended period

- Activities in a building (e.g., showers) that lack exhaust ventilation (including openable windows)

Materials that support mold growth are porous and contain carbon. These include gypsum wallboard, carpeting, cloth, paper/cardboard, ceiling tiles, and wood materials. Mold can also grow on dust and paint on the surface of semi-porous or non-porous materials such as metal, wood, plastic, brick, and plaster.

State regulations -- 105 CMR 410.000 Minimum Standards of Fitness for Human Habitation within the State Sanitary Code, Chapter II (105 CMR 410) address excess moisture and mold inside buildings. The state’s nuisance law -- General Law - Part I, Title XVI, Chapter 111, Section 122 – directs local Boards of Health to examine and take enforcement actions against sanitary conditions, which may include moisture and mold.

Moisture Measuring Devices (MMD)

MMDs measure electrical resistance. Materials such as gypsum wallboard, plaster, and wood will not readily conduct electrical current when they are dry and intact. The addition of water to these materials increases their electrical conductivity. MMDs measure the conductivity of electricity through the sampled material. For ease of recording material moisture levels, we recommend an MMD with digital readout.

These devices either have pins or are pinless. Both types operate using similar principles.

- The pins of an MMD provide two ends of an electrical circuit which, when inserted into wet material, create an electrical current. The MMD, by measuring the strength of the electrical current traveling between the pin probes, estimates the moisture content of the sampled material, expressed as a percentage. The user can extend the probe of a pin-based MMD to reach ceilings and tall surfaces. The pins, however, can damage materials such as wallboard.

- A pinless MMD is not destructive. A sensor plate on the back of the meter projects an electrical field into a material’s surface. The device senses electrical changes caused by moisture in the material. To ensure an accurate measurement, the sensor plate must be flush with the surface sampled.

You can use MMDs to measure moisture levels in plaster, wood, gypsum wallboard (GW), concrete, and brick by choosing the appropriate material setting. MMDs can also be used for other materials such as carpeting. For carpeting, we recommend using the wood setting or consulting your device’s manual.

Interpreting Moisture Meter Readings

MMDs typically have a scale to show whether a material has moisture at levels expected, slightly elevated, or saturated. Consult the user guide for your device to understand the numeric readings for particular materials.

Sampling Considerations

You should conduct moisture sampling indoors in at least two separate locations: the suspect material and the same material at a location not suspected of having a moisture problem (the control location). Sampling in the control location is necessary for comparison to ensure that the measurements are accurate.

Relative humidity greater than 70% can provide enough water vapor in the air to moisten building materials. Extended exposure to relative humidity in excess of 70% can result in mold growth.

- If you sample in hot, humid weather, the relative humidity of the ambient air may be sufficient to indicate the presence of water in sampled materials.

For any moisture sampling protocol, measure the temperature and relative humidity outdoors and indoors in unaffected areas and in the area of concern. Various instruments are available to measure temperature and relative humidity. Weather data from a nearby weather station can also be used to estimate outdoor conditions.

Sampling Protocols

Staff in the Indoor Air Quality Outreach and Education Unit use the following moisture sampling procedures to determine if materials should be removed.

For Gypsum Wallboard (GW) with No Visible Mold Growth or Water Damage

When water damage is not visible and no obvious water leak or flood has occurred, measuring the water content of building materials can help determine if the moisture content of GW is uniform throughout the building (due to atmospheric humidity) or whether a less obvious source (e.g., intermittent window leak) is the cause of the excess moisture in the GW.

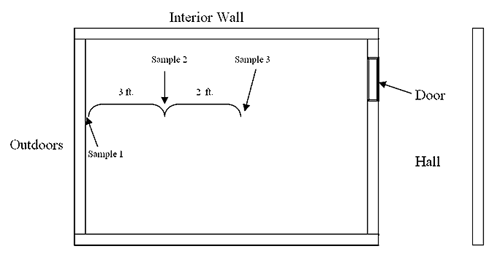

In this situation, we recommend sampling as many rooms as possible to see if a pattern exists. Sample a minimum of three locations in each area being investigated (Figure 1):

- the area of suspected water damage (usually an exterior wall);

- the center of a wall between rooms on the same exterior wall; and

- a hallway wall.

Compare the moisture content to determine if one location contains more moisture than others. Then compare moisture sampling data to the control area sample. If the majority of moisture measurements are similar, the source of moisture measured in the GW is likely a result of atmospheric relative humidity and not a hidden leak.

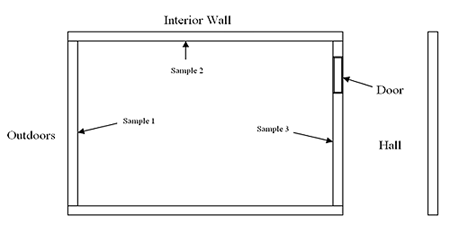

For Gypsum Wallboard with Visible Water Damage but No Mold Growth

Sample gypsum wallboard in affected areas and control areas. This material readily absorbs and “wicks” water via capillary action and so can be moist a significant distance above the standing water level. Begin sampling at the base of the wall. Take each subsequent sample in regular intervals (about 3 inches apart) up the wall. When

moisture measurements indicate the material is dry, mark the area to indicate the height where moist wallboard is present. If the wallboard has been wet for more than 24 to 48 hours, remove all of it below this mark and an additional foot above the mark.

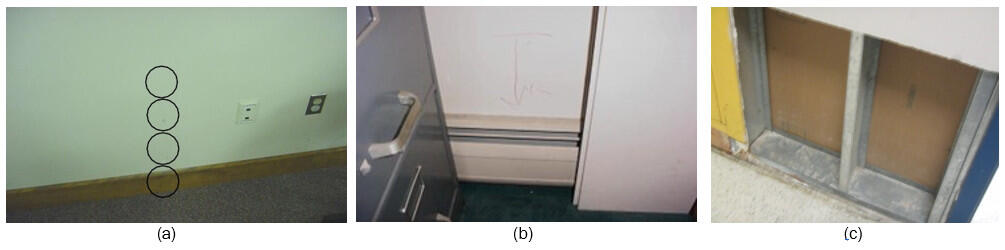

For Carpeting

MMDs can be used to determine if other materials are moist, such as wall-to-wall

carpeting. For carpeting, use the “wood” setting. A range of 0-15 percent represents the dry (non-moistened) range. Take a control sample in an area not affected by the water damage, for example on a floor above the suspect area. Take moisture samples in carpets throughout the building. Place the MMD on or insert it into the surface of carpeting directly next to the wall/slab and near the location of suspected water damage for the 1st reading, and approximately 3 feet away from the first location for the 2nd reading. If you detect moisture in the 3 feet measurement, take a third reading approximately 5 feet from the first location (Figure 3).

Repeat this process at two-foot intervals until measurements are either equal to the control measurement or non-detectable. If the source of moisture in the carpet is atmospheric (e.g., humidity), moisture readings across the carpet should be relatively uniform (i.e., with a narrow variation of ±2%). Significant variation in the moisture content indicates that the carpet is moist and should be dried and/or removed.

Identifying the Source of Water

While water staining or pooling water is an obvious sign of moisture, many materials do not appear visibly wet even when saturated enough to support mold growth. If water damage is suspected, examine conditions around the area to identify potential leaks from water pipes or ventilation equipment. In the absence of plumbing failure or high relative humidity levels, weather events are most commonly the cause for water damage in a building. Note the amount of rainfall and general wind direction of the last significant rainfall prior to the sampling. Use this information to see if it corresponds to the location in the building where moistened materials were found. The date of the weather event can be used to estimate how long the materials have been wet.

The U.S. Environmental Protection Agency (EPA) recommends that materials be dried within 24 to 48 hours. If rainfall events are the likely source of moisture and the rainfall occurred 24 to 48 hours or more prior to moisture sampling, it is highly likely these materials have been wet long enough to be subject to microbial growth. These materials should be removed and replaced. If the rainfall is within 24 hours, drying the materials with fans and heat may be sufficient. A MMD should be used to re-test moisture content following drying. Materials that remain wet after 48 hours should be removed and replaced.

Remediation of Moistened Materials

To minimize exposure to building occupants, remove mold-contaminated materials in a manner that prevents cross contamination of clean areas. Follow EPA guidelines in its document “Mold Remediation in Schools and Commercial Buildings”.

Additional Resources

-

Open PDF file, 193.36 KB, Use of Moisture Measuring Devices for Evaluating Water Damage in Buildings (English, PDF 193.36 KB)