Background

GKN Sinter Metals Corporation, with a facility located in Worcester, Massachusetts, is the world’s leading producer of structural powdered metal components for the automotive industry. The Worcester company was founded in 1943 as a division of Massachusetts Steel Treating Corporation (MST) and employs 230 people. In 1994, when GKN noticed that amounts of copper, fats, oil, and grease in its wastewater exceeded the limits established by the local POTW, the company began to investigate available technologies that would reduce wastewater discharge concentrations and conserve water.

Process Description

More than 75% of GKN finished parts are processed through the tumbling operation, both as a way to remove metal burrs and to clean parts. The compaction process results in the formation of small burrs of metal on the finished components, which must be removed for certain applications. The burrs are removed through a process carried out in vibratory bowls, usually with ceramic media, which “cuts” the burrs as the bowls are vibrated.

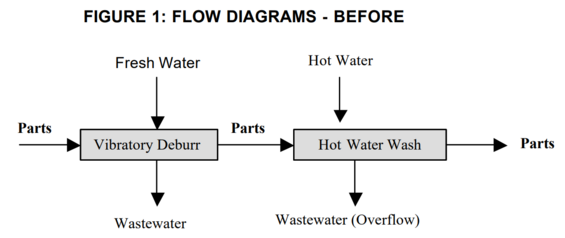

Prior to the installation of the ultrafiltration unit, the company cleaned some of the parts by tumbling them in the bowls. As shown in Figure 1, fresh water, mixed with soap, was continuously fed to these processes and then discharged to the sewer. After processing, the parts were rinsed with hot water and then discharged onto a vibratory screen to separate the ceramic media from the parts. Wastewater was then discharged directly into the sub-floor drainage pit, which accumulated the ceramic media sludge and drained the water.

Original parts cleaning process

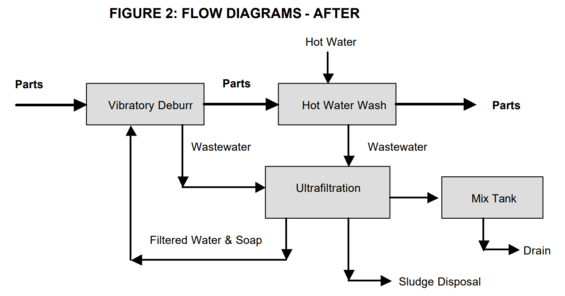

In the new system (Fig. 2), which uses a Hyde Ultrafiltration HUF-4/6-VIB unit, the sub-floor drainage has been closed off and re-routed to the ultrafiltration system. The discharge (clean permeate) is fed continuously to the Sweco vibratory deburring units during the processing of parts. No discharge is made to the sewer during operation. Some of the flow from the ultrafiltration unit is discharged to an acid mix tank for pH adjustment. Total discharge, comprising of a small volume of treated water from the tank and some recycled water used to clean sludge from the pit, and averaging less than 100 gallons a day, is discharged to the sewer.

Modified parts cleaning process

Results

Reductions

Since the system came on line, the company reduced their average water use from 8,428,750 gallons per year to 30,744 gallons per year and their soap use from 7,000 gallons per year to 210 gallons per year. The company also reduced the amount of copper discharged to the sewer, from 100 mg/l to less than 10 mg/l, within the current limit established by the POTW of 174.25 mg/l and fats, oils, and grease combined discharged to the sewer from 220 mg/l to 100 mg/l, well within the current limit established by the POTW of 225 mg/l.

Economics

Before installation of the Hyde Ultrafiltration system, GKN Sinter Metals spent close to $83,700.00 per year on water, soap, and disposal costs. After the installation, the company reduced these costs to nearly $5,500.00 per year. The total cost of the system, including installation was about $120,000 and the total savings per year from their reduced water and soap consumption and disposal costs is $78,220.00 per year, making the total payback period about 18 months.

Improving Worker Health and Safety

To improve worker health and safety at the facility, the company added a new delivery system for calcium carbonate, now pumped into a silo and then pumped directly to the mixing vessels. This eliminates the need for workers to haul and break open bags of powder, reducing dust levels and paper waste. Where workers once had to lift 75 pound pails of paint from a conveyer belt to place them on pallets for shipping, Franklin Paint has recently installed an overhead lift, reducing strain on workers. “Our people are the most important factor we have,” said Schultz. “We want to keep them as long as we can and we want to keep them healthy.”

Conclusion

Franklin Paint has eliminated the use of two TURA reportable substances and reduced the use of three others, resulting in an annual decrease of 900,000 pounds of reportable toxic use. The company not only significantly reduced toxics use, but increased product production over the same time period. Boise and Schultz also continue to adopt practices that improve worker health and safety and look for opportunities to reduce their products impact on the environment.

Published 2015