Toxics Use Reduction

Implementation of Lean Manufacturing and Six Sigma

Ophir started their journey towards a more sustainable operation in early 2009 when the company conducted internal training and implemented continuous flow in its manufacturing areas. This process was accelerated in 2010 when Ophir received a workforce training grant from the Commonwealth of Massachusetts to undertake training in Lean Manufacturing, Six Sigma, and management methodologies designed to create a more efficient overall manufacturing process. Ophir teamed up with a non‐profit Lean Manufacturing consulting organization, Greater Boston Manufacturing Partnership (GBMP), to provide the training.

During this same time period, Ophir contacted the Massachusetts Office of Technical Assistance (OTA) for ideas and assistance in reducing its generation of hazardous waste. OTA engineers evaluated the processes that use toxic chemicals and create hazardous waste, and provided a number of suggestions for reducing toxics use and hazardous waste generation. Based on OTA’s recommendations Ophir embarked on a series of continuous improvement projects, using the Six Sigma process where appropriate.

The basic concept of Six Sigma is that processes have characteristics that can be measured, analyzed, improved and controlled. The Six Sigma approach is implemented through a group effort that motivates commitment from the entire organization to achieve sustained quality improvement.

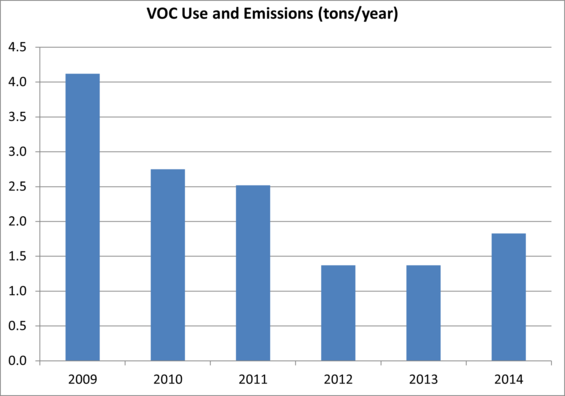

Ophir used Six Sigma tools to implement a suggestion by OTA that it could decrease the use and emissions of mineral spirits, a toxic and volatile organic compound (VOC), used as a coolant in their diamond turning manufacturing process. Anticipating an increase in production, Ophir was concerned about increased costs associated with compliance with air emissions regulations. Ophir evaluated the technical performance of three Low-VOC coolants identified with OTA’s assistance. Ophir investigated water‐based coolants and determined that substitution could provide higher quality results, but Ophir would need to fully design a fluid capture and solids removal system to implement the change. Therefore, as a short term solution, Ophir investigated methods for increasing the efficiency of its use of volatile organic compounds in the diamond cutting process.

35 mm f/1.4 athermalized lens

After closely monitoring the use of mineral spirits at each machine and measuring product quality, Ophir determined that even with significant reductions in the use of mineral spirit there was no diminution in lens functioning. The careful identification of key factors and measurement and control of operating parameters that is a hallmark of the Six Sigma process brought about even further reductions in mineral spirit usage in the machines with the lowest use rates. Each cutting machine operator was then instructed to set the flow controls for delivery of mineral spirits to the cutting site within a tight set of application parameters. Average delivery rates were reduced by 70%.

25-225 mm f/1.5 continuous zoom lens

Mineral spirit consumption had increased along with production from 2008 to 2009. However, even though production held steady in 2010, with the implementation of these changes, Ophir was able to reduce its mineral spirit consumption by 3,870 pounds. Faster lens production has saved an additional 2,300 pounds per year, but demand for more complex lenses will increase consumption somewhat. The total estimated annual savings for the VOC project is $15,000. In addition, the careful measurement and evaluation of the diamond turning process has enhanced overall production quality, with fewer adjustments necessary during production. Ophir will also save on time and air permitting costs by avoiding the increase in emissions.

VOC use and emissions (tons/year)

In addition to the VOC reduction project, Ophir also looked into OTA’s recommendation that, as good general practice, processes should be redesigned to avoid mixing together germanium and selenium waste streams. Implementing this suggestion was not difficult for Ophir, and during 2010, the facility reduced the quantity of hazardous waste shipped by about two‐thirds. Whereas during the first half of the year the company was a large-quantity generator of hazardous waste (the threshold is 1,000 kilograms per month), during the second half of the year Ophir was able to reclassify itself as a small-quantity hazardous waste generator, with shipments well below 1,000 kilograms of hazardous waste per month. Associated training, hazardous waste management and reporting requirements were also reduced.

Other Lean Manufacturing and Six Sigma projects implemented at the facility that have made Ophir’s production process more efficient include:

- Cellular layout of lens fabrication which facilitated the switch from batch manufacturing to continuous flow production. This reduced work in process inventory, labor, and overall lead time to produce the product.

- Total productive maintenance (TPM) in several departments, including daily checks of equipment and visuals which allow operators to easily confirm that equipment is within proper operating parameters.

- 5S methods (sort, straighten, shine, standardize, and sustain) throughout the plant. This is a method of organization that reduces wastes such as searching for tools. Supplies and tools are now stored at point of use and organized in a standardized way that facilitates operator/technician use.

- Recognition programs to motivate participation by employees, including both team rewards and individual employee awards. For example, teams were recognized in a variety of ways such as plaques, gift cards, and shirts.

- Standardized work projects, which help balance the production flow and eliminate waste and manufacturing bottlenecks.

- Scrap reduction projects utilizing the Six Sigma process DMAIC (Define, Measure, Analyze, Improve, and Control).

Results Achieved

The results achieved by Ophir Optics’ implementation of Lean Manufacturing and Six Sigma improvement projects include:

- More than $1,000,000 in efficiency improvements was achieved from implementing Lean Manufacturing and Six Sigma projects. The majority of this was achieved through the implementation of continuous flow cells and standardized work.

- Ophir also achieved more than $100,000 in projected scrap reductions from Six Sigma projects.

- Savings associated with hazardous waste reductions in excess of $60,000.

- Less facility space (saved 1400 square feet) and capital equipment required, also better manufacturing throughput with a fixed amount of resources.

- An overall reduction of 70% in the time to manufacture lens elements.

- New business opportunities generated through reduced cost and new products. Ophir was able to offer products at lower cost and designed new coatings using the Six Sigma process.

Summary

Ophir has been very successful in using Lean Manufacturing and Six Sigma techniques to reduce their use of resources such as facility space, production equipment, and energy. In addition, Ophir’s implementation of continuous improvement projects has been successful in reducing hazardous waste. Ophir also used Six Sigma to pursue OTA’s recommendation to reduce use of VOCs (mineral spirits), while improving an already well-controlled production process.

In conclusion, the application of Lean Manufacturing and Six Sigma strategies and tools has facilitated many “green” initiatives, including toxics use reduction and resource conservation, in a manner that is consistent with other Ophir business goals such as quality, cost, and delivery.

Download

Published 2015