Background

V.H. Blackinton & Co., Inc., is the largest manufacturer in the United States of metal uniform insignia such as badges, medals and service pins. The company also makes jewelry and other metal plated novelties. With a staff of 210 people, the company manufactures products from start to finish; from designing artwork to processing raw materials to packaging products for shipping. The manufacturing operations include blanking, stamping, punching and machining raw stock prior to cleaning, enameling, brazing, polishing, plating and finishing.

Energy Efficiency

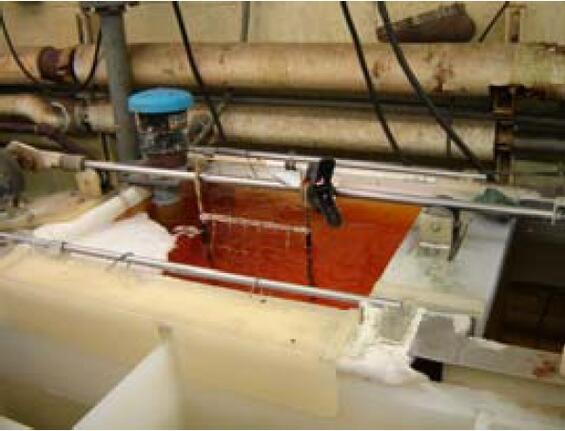

Silver plating

Recently, Blackinton has replaced their oil-fired boilers with two high efficiency condensing natural gas boilers. The company received a $15,000 utility incentive for each boiler. Each boiler has a capacity rating of 2.5 million BTU’s. Blackinton also is in the process of a relamping project, which has further enhanced their energy conservation efforts. The company expects to save $60,000 to $80,000 per year in energy costs.

Toxics Use Reduction

The company streamlined its plating and finishing processes in the early 1990’s to meet increasing product demand and more stringent environmental requirements. In doing so, they eliminated Freon used in parts drying, and closed the loop on plating rinse water and wastewater discharges. By May of 2001, the company eliminated the use of over 25,000 gallons of water per day and cut individual chemical use ranging from 40 to 100 percent.

During the 1990’s the company switched from using Trichloroethylene (TCE) for parts cleaning to an aqueous system. The switch to aqueous cleaning, combined with other process changes, allowed the company to completely eliminate a bright dipping step. The badge clasps, which used to be loosened in the bright dipping step, are now freed during the aqueous cleaning. Bright dipping also added significant amounts of copper and zinc metals to the wastewater treatment system that generated large quantities of metal hydroxide sludge in waste treatment and large quantities of waste sulfuric acid, which was neutralized with sodium hydroxide. Eliminating this step reduced the copper and zinc loading to the wastewater by 85 percent, reduced sulfuric acid by nearly 700 pounds per year and sodium hydroxide use by more than 5,700 pounds per year. During the same time period, Blackinton also reduced cyanide use by 90 percent. This was achieved by reducing the size of the plating tanks from 60 gallons to 10 gallons, decreasing the concentration of cyanide in the plating bath, and partially replacing the cyanide/hydrogen peroxide bombing process with less toxic sulfuric acid/hydrogen peroxide and phosphoric acid/hydrogen peroxide bombing process. The “bombing process” removes fire scale from final the product. These changes, along with switching from a 2-stage to a single stage cyanide destruction, also reduced the amount of sodium hypochlorite (bleach) by more than 90 percent.

“TUR is not a onetime occurrence, but an ongoing effort to reduce, control and eliminate the use of toxic materials and waste no matter how insignificant the opportunity may seem. Acting on and realizing smaller cases of TUR today will prevent the growth of toxics use tomorrow.”

In 2003, Blackinton installed new brazing furnaces with 12 inch belts rather than 6 inch belts that allowed the company to process twice the amount of work as the old furnaces. The replacement furnaces use a 25 percent hydrogen and 75 percent nitrogen mix, eliminating the use of more than 20,000 pounds of disassociated anhydrous ammonia annually. The company also conserves 5,000 gallons of cooling water per day that was once routed to the plating room for rinsing after use in the furnace; it is instead close-looped, chilled and returned to the furnaces.

Water Conservation

Natural gas boilers

In addition to the 5,000 gallons/day conserved through the closed-loop cooling water system, Blackinton also modified their wastewater treatment system to incorporate the use of a vacuum distillation unit. The technology recovers distilled water from the wastewater that can be reused in the plating process. Concentrated dissolved salts from the distillation system are dried and disposed of as a hazardous waste. This technology along with modernizing the plating line conserved 20,000 gallons of water per day and reduced sulfuric acid and sodium hydroxide use by an additional 25 percent. Blackinton also switched to magnesium hydroxide for all pH adjustment, which is safer and less toxic to use than sodium hydroxide. The company generates approximately six tons of hazardous waste per year from the enclosed evaporator, down from the 35 tons per year generated from the previous conventional flow-through wastewater treatment system – a reduction of 58,000 pounds of hazardous waste per year.

Results

Blackinton has realized savings on chemical purchases, disposal costs, regulatory monitoring, reporting and permitting fees, and water and sewer use charges. The company is also no longer required to pay TURA (Toxic Use Reduction Act) fees, a savings of $5,725 per year. Additionally, the company has saved $12,500 annually in purchasing, management, and treatment costs from the reduced use of toxic chemicals. The cost to install the nitrogen/hydrogen furnace system was $18,110. Blackinton saves approximately $5,000 per year in water and sewer charges and $2000 in operating costs with the new system. The elimination of the TURA fees would have paid for the system within three years, but with the savings in operating costs, the payback period was reduced to less than a year and a half. The recent implementation of energy conservation measures has saved the company around $60,000 to $80,000 annually. Blackinton’s annual savings compared to its costs in the early 1990s are an estimated $112,725 per year.

Download

Published 2012