Download this Fact Sheet as a PDF

Best Practices and Benefits

Tightly Seal Containers When Not in Use

Keep harmful vapors out of the air by keeping containers tightly sealed when not in use. This practice will save you purchasing costs by keeping paints and solvents from evaporating.

Install a Well-Designed Ventilation System

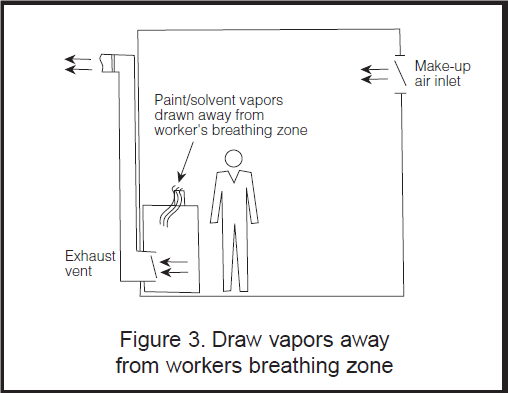

Follow US EPA’s recommendations on setting up a safe paint mixing area. An effective paint room ventilation set up will use both local exhaust and general ventilation to bring in fresh air from the outside, while drawing hazardous air outdoors. US EPA describes the ideal set up as having:

- Local exhaust to draw chemicals from the work area and away from the workers personal breathing zone. Local exhaust ventilation systems always consists of three basic components:

- An exhaust vent or special duct end installed as close as possible to where work is performed and the source of hazard that ensures that vapors do not get pulled upward across the workers personal breathing zone (ideally sideways or downdraft, rather than pulling the air upward), to capture the vapors;

- Ductwork to transport the vapors from the hood to outside the building; and

- A fan located downstream of the hood to draw air away from the work area, through the hood and ductwork, and discharge it from the building.

- Make-up air that is located where it cannot push hazardous air into the workers personal breathing zone and located on the opposite side of the room than the exhaust air.

- Continuous movement of air so that there is no opportunity for chemicals to build up in the paint mixing room.

- Exhaust vents located at a low level to remove low-lying vapors.

Close the Mixing Room Door

Closing the door prevents vapors in the mixing room from entering the rest of shop. This helps protect the health of both workers and customers.

Exhaust Gun Wash Vapors

The Massachusetts Department of Environmental Protection (MassDEP) requires spray guns to be cleaned in devices that minimize solvent evaporation. You can improve mixing room air quality even further by installing a gun cleaner with an exhaust fan that removes vapors from the room and by ensuring that the gun cleaner maintains a tight seal whenever operating. You can also change from a solvent gun washing solution to a safer, non-flammable, and more economical alternative chemical (See Water-Based Gun Washing fact sheet).

Wear Supplied Air or Air-Purifying Respirators

The use of supplied air or air-purifying respirators provide fresh air to workers while they work in the paint mixing room, reducing harmful exposure to paint and solvent vapors. Cartridge filters are allowed, but you must be vigilant to make sure that they are stored properly in a plastic bag and do not expire since cartridges have a limited lifetime. All workers must be fit tested and medically cleared for any respirator use. You are responsible for all of OSHA’s requirements to reduce workplace exposures. You can see OSHA’s respirator requirements and educational material and videos on creating a respiratory program.

Protect Your Eyes

Safety glasses protect the worker’s eyes and face when pouring paints or other toxic chemicals. They also prevent workers from accidentally rubbing their eyes during mixing room operations.

Protect Your Skin

The use of nitrile or neoprene gloves prevents skin contact with harmful chemicals. Latex gloves are designed to protect you from germs and bacteria, but do not provide adequate protection against solvents.

Use a Computerized Paint Mixing System

Computerized paint mixing systems help determine the exact quantities of primers, basecoats, and clear coats to mix for a given job. These systems minimize paint waste and help shops save money. Such systems help you track the total quantities of paint your shop uses, which can document your compliance with MassDEP regulations. If your shop is not already equipped with a computerized mixing system, contact your supplier or your paint manufacturer to learn what options are available.

Diagram of EPA's ideal ventilation system for a paint mixing room.

Find Additional Information

- Follow US EPA’s recommendations on setting up a safe paint mixing area. An effective paint room ventilation set-up will use both local exhaust and general ventilation to bring in fresh air from the outside, while drawing hazardous air outdoors.

- See the Body Shop Business article Your Lungs, Your Skin, Your Life for information on safety precautions for working with isocyanates.

- See EPA’s Best Practices for the Paint Mixing Room fact sheet.

Success Stories

“We recognize that our painters spend quite a bit of time in the mixing room, so we do our best to ensure that the air is as clean in there as possible. We’ve ensured the room is properly ventilated. We use enclosed spray gun cleaners. All waste collection and containers are always capped. They have the appropriate personal protective equipment available at all times.”

Contact

Phone

You will be connected to the person who can best answer your questions.