Background

Paper produced by Seaman Paper

Seaman Paper Company of Massachusetts, Inc. is a privately owned paper company located in Otter River, employing 100 people. The plant operates around 350 days a year, seven days a week, producing on average 70 tons per day of decorative tissue paper. Some of the paper produced in Otter River is transferred to nearby plants in Gardner and Orange for printing and converting into specialty products. Seaman produces tissue reams, crepe streamers, tissue gift wrap and waxed foodservice papers.

Energy Use and Savings

In an earlier case study published in 2008, OTA reported that Seaman Paper had established an aggressive energy conservation program that led to significant reductions in both energy use and operating costs. This program included replacing lights with more energy efficient lighting, using variable frequency drives on various motors, and the installation of a heat exchanger. These projects reduced annual electrical energy use by 3 million kWh, and fuel oil consumption by 480,000 gallons, and saved a total of $1.44 million.

Electricity Reduction

Variable frequency drives

Seaman Paper achieved electrical energy use reductions by various means. More efficient lighting was installed throughout the plant. The T8 fluorescent bulbs installed are brighter, have a smaller diameter than common fluorescent lamps, and provide a superior quality of light. The company also installed 58 variable frequency drives (VFDs). These drives use sensors to determine power needs and to match the output of the device (such as a motor) to the job it needs to do. VFDs were used in combination with brakes known as regeneration brakes, replacing friction brakes on the tissue winders.

Regeneration brakes absorb the power of braking as recaptured electrical energy instead of dissipating it as heat, as friction brakes do. These brakes also experience less physical wear than friction brakes and thus have a longer life. Seaman also replaced some eddy current drives with VFDs. The eddy current drives used magnetic clutches that had slip and were less efficient than the VFDs. The payback period on these improvements was between one and three years. These improvements reduced electricity use by 3 million kWh per year, equivalent to $300,000 in today’s electricity prices.

Heat Exchanger

Seaman Paper uses steam to heat large, cylindrical dryers that process the newly made paper. Some of the steam passes through without condensing, and thus without transferring its latent heat. This is called “blowthrough” steam. To capture this heat, Seaman installed thermocompressors, which repressurize the low pressure steam, so that it can be reused in the dryers. Seaman is also recovering energy from some of the condensate stream. When hot condensate in a pressurized system is released at a lower pressure, some of the condensate will become steam. This is called flash steam, which Seaman once vented, producing a waste energy stream. Seaman installed an economizer/heat exchanger in 1999 to recover this waste energy and now uses it to preheat boiler feedwater makeup and incoming process water. By 2011, Seaman Paper was able to replace a total of 38,848 barrels of oil (1,631,616 gallons) with 27,353 tons of shredded wood pallets for a net fuel savings of $3 million using current oil prices.

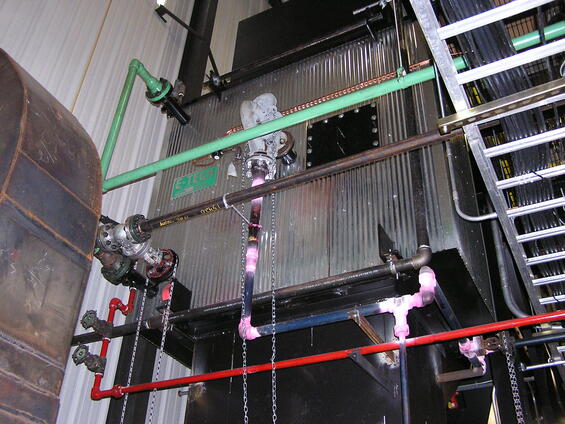

Economizer/heat exchanger

Seaman also recycles 28 of its wastewater effluent back to the intake of the plant for reuse in the process, which reduces the energy needed to heat fresh water. This has also reduced Seaman’s fresh water demand by 131 million gallons per year. In the winter, the differential between the river water and the recycled effluent can be as high as 26° F, representing significant energy savings.

“We’re very pleased to look back at what we’ve done, and see the significant reductions in carbon dioxide and other emissions. It feels good to see that because everyone has to try to play a part in addressing these important issues.”

Two Wood-Fired Boilers

Wood-fired boiler

Seaman Paper added its first wood-fired boiler (with baghouse filters) in 2007, which reduced oil use by an additional 1.3 million gallons per year, lowering annual emissions by more than 31 million pounds of carbon dioxide from the 1999 base year. A second wood-fired boiler was added in 2009, which along with a backpressure steam turbine/generator, further reduced oil use to 1.7 million gallons per year. The two boilers also reduced nitrogen oxide emissions by 27 percent (13 tons) and sulfur dioxide emissions by 95 percent (128 tons). The two wood-fired boilers allowed the company to save $3 million in fuel costs.

Backpressure Steam Turbine

Backpressure steam turbine

In 2009, Seaman Paper also installed a backpressure steam turbine, to generate electricity and process steam for the plant. Superheated steam from the wood-fired boiler is expanded through the turbine/generator producing electricity at a cost far below the current utility rate. The turbine exhaust steam is used in the paper making process. From 2009-2011, the backpressure generator produced more than 3,000,000 kWh of electricity, reducing annual energy costs by more than $200,000 through lower fuel costs and the sale of Renewable Energy Credits (RECs) for the electricity it produces. This also amounted to a 5,892,000 pound reduction in annual CO2 emissions.

Benefits of Cleaner Technology

Bag house filter

According to Seaman Paper’s president, George D. Jones, these measures have saved the company millions of dollars. “I would have done all of these things even if they weren’t good for the environment because they have kept us competitive in the global marketplace,” said Mr. Jones. “We’re very pleased to look back at what we’ve done, and see the significant reductions in carbon dioxide and other emissions. It feels good to see that because everyone has to try to play a part in addressing these important issues.” Jones also expressed appreciation for useful advice received from a free assessment provided by the Industrial Assessment Center at UMass Amherst, a program funded through a partnership between the state and the U.S. Department of Energy.

Results

| Project | Annual Material/Resource Reductions or Savings | Annual Cost Savings |

|---|---|---|

| Thermocompressors, heat exchanger, effluent recycling reduced steam use | 60 million pounds of steam/11,429 barrels of oil | $1,143,000 |

| Energy efficiency improvements (lighting, VFDs, alternative heating) | 3 million kWh of electricity | $300,000 |

| 2 wood-fired boilers | 38,343 barrels of oil/13 tons less NOX emissions/128 tons less SO2 emissions | $3,000,000 |

| Backpressure turbine | 1.5 million kWh of electricity | $200,000 |

| Total | $4,643,000 |

New Energy Project

In 2010, Seaman Paper started up a landfill gas project (called Seaman Energy) where methane from a local landfill is used to power reciprocating engines that produce 300-500 kW of electricity. Seaman Energy has produced 6.4 million kWh of electricity since its start-up to 12/31/2011 from gas that would have been flared to atmosphere.

Recycling at Seaman Paper

- Seaman uses 60 percent pre-consumer recycled fiber and also introduces postconsumer fiber into its Satin Wrap retail packaging line and selected resale tissue accounts.

- Seaman is certified for Chain of Custody under the Sustainable Forestry Initiative Program (SFI), the Programme for the Endorsement of Forest Certification schemes (PEFC) and the Forest Stewardship Council (FSC) Program. These programs provide independent third party verification that fiber used in the operation comes from sources that promote sustainability and minimize environmental impact.

- Seaman collects fiber and cores that it cannot recycle back into its products and sells the paper back to jobbers for recycling by other mills. Seaman collects its office waste for recycling.

- Cores, plugs and headers are collected at the Seaman converting plants and returned to the mill for reuse.

- Residuals from Seaman’s treatment plant and fly ash from the boiler are composted at Seaman’s 300 acre composting site in Westminster, Massachusetts; the bottom ash is used as a cover material.

Download

Published 2013